Understanding Sydney’s Steel Rigging Requirements and Industry Standards

Sydney’s construction industry is booming, with high-rise towers, infrastructure projects, and large-scale industrial developments reshaping the city. Behind every one of these builds is steel rigging—the complex and high-risk process of lifting, positioning, and installing massive steel components safely and efficiently.

For project managers, understanding steel rigging in Sydney is non-negotiable. Between strict safety codes, tight urban site constraints, and heavy multi-tonne lifts, only skilled, certified rigging crews with local expertise can ensure projects stay safe, compliant, and on schedule.

In this article, we’ll cover:

- The importance of steel rigging for Sydney projects.

- Common challenges and risks on local job sites.

- NSW regulations and codes you need to follow.

- Why local expertise makes a difference.

- How to choose the right steel rigging partner.

- Real-life case studies and future trends shaping the industry.

Why Steel Rigging is Critical for Sydney’s Construction Projects

Steel rigging is the backbone of structural steel erection. Without experienced riggers, beams, trusses, and columns cannot be safely lifted or accurately positioned.

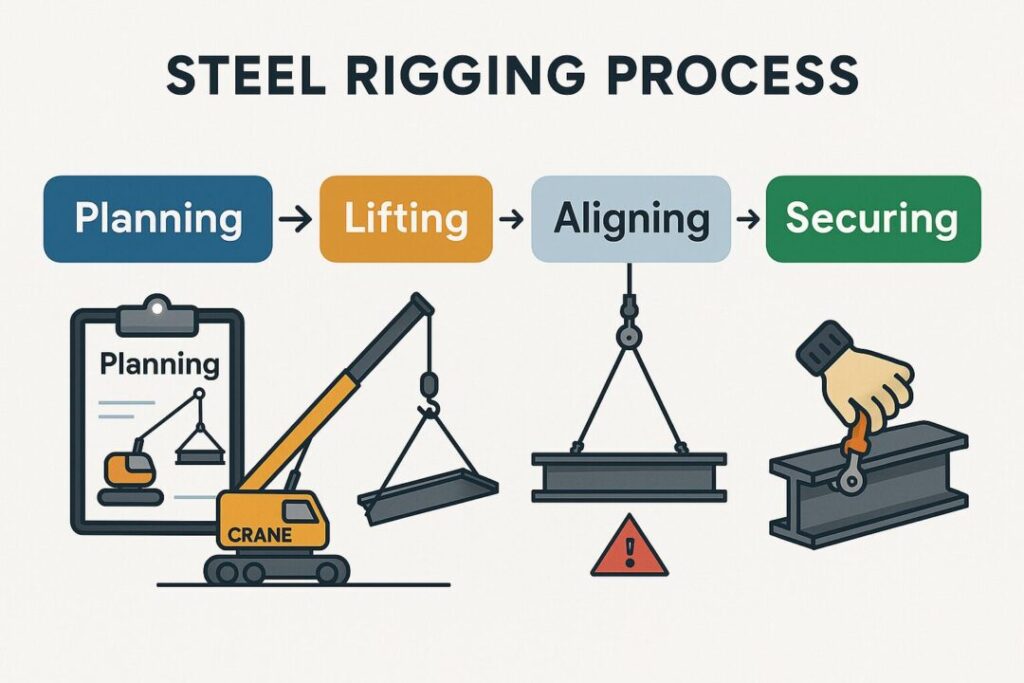

What Steel Rigging Involves

- Using cranes, slings, shackles, and spreader beams to lift heavy components.

- Aligning steel precisely for welding or bolting.

- Controlling loads during complex manoeuvres to prevent accidents.

Why It Matters in Sydney

- High-rise towers: Require precision rigging to install frameworks safely at great heights.

- Infrastructure projects: From train stations to bridges, steel rigging supports Sydney’s biggest builds.

- Industrial facilities: Warehouses, schools, and factories all rely on secure steel frameworks.

Effective rigging ensures:

- Structural integrity by avoiding misalignments or weak connections.

- Safety on-site with controlled, stable lifts.

- Efficient timelines, reducing costly delays and rework.

Challenges of Steel Rigging in Sydney

Sydney’s construction landscape presents unique obstacles that only experienced riggers can navigate.

Limited Site Space and Access

- CBD sites often have narrow access points and overhead obstructions such as power lines.

- Cranes may require road closures or permits to be set up safely.

Heavy and Complex Lifts

- Large steel beams or prefabricated structures can weigh 200 tonnes or more.

- Detailed rigging plans and proper sling angles are crucial to avoid unstable lifts.

- High-capacity cranes (30T–300T) are often needed for these operations.

Weather and Environmental Conditions

- High winds can swing or destabilise loads.

- Rain or wet surfaces impact crane footing.

- Sydney’s summer heat increases worker fatigue and risk factors.

Communication Breakdowns

- Lifting requires perfect coordination between crane operators, riggers, and supervisors.

- Without clear signals or reliable radios, misaligned or unsafe lifts can occur.

Strict Safety Requirements

- Steel rigging is classified as high-risk work in NSW.

- Failing to follow safety codes can lead to heavy fines, project delays, or serious incidents.

NSW Steel Rigging Regulations and Safety Codes

Every steel lift in Sydney must meet strict legal and industry standards to ensure workplace safety.

High-Risk Work Licensing

- All riggers, dogmen, and crane operators must hold a valid HRW licence issued by SafeWork NSW.

Australian Standards

- AS 2550: Safe use of cranes, hoists, and winches.

- AS 1418: Design, testing, and maintenance of lifting gear.

- ISO 45001: Occupational health and safety systems.

- AS/NZS ISO 3834: Welding quality for steel fabrication.

WHS Act 2011 Compliance

- Employers need to provide a safe work environment, including risk assessments, SWMS, exclusion zones, and fall protection.

Essential Documentation

- Rigging Plan: Details lift sequence, crane setup, and safety measures.

- Load Test Certificates: Verifies lifting gear capacity.

- Crane Inspection Logs: Daily pre-start checks and annual certifications.

Why Local Know-How Matters in Sydney Steel Rigging

Local expertise ensures projects are completed safely, on time, and on budget.

Site Access and Permits

- Local contractors know council processes for road closures, traffic management, and crane positioning.

- They understand Sydney’s tight CBD layouts and access constraints.

Weather-Ready Planning

- Knowledge of Sydney’s wind patterns and rain cycles helps avoid weather-related delays and risks.

Established Supplier Networks

- Access to cranes, trucks, and replacement rigging gear ensures minimal downtime.

Proven Track Record

Hard Bakka Rigging has delivered major NSW projects, including:

- Snowy Hydro 2.0: Renewable energy infrastructure.

- Redfern Station Upgrade: Complex rigging in live rail conditions.

- Dozens of school COLA installations across Greater Sydney.

Choosing the Right Steel Rigging Contractor

The right partner can make or break your project. Look for a company with:

- ✅ Certified riggers and crane operators with HRW licences.

- ✅ ISO 9001, 14001, and 45001 certifications.

- ✅ Proven experience in critical lifts up to 300T.

- ✅ Detailed rigging plans and SWMS provided upfront.

- ✅ Positive client testimonials and a strong safety record.

Key Questions to Ask

- How do you handle critical lifts exceeding 75% of crane capacity?

- What contingency plans are in place for weather delays?

- Can you provide recent safety statistics and project references?

Case Study: Precision Rigging on a Tight Sydney Site

Hard Bakka Rigging was contracted for a childcare centre project in Picton with limited site access and complex sequential lifts.

- Challenge: Restricted crane setup area, multiple heavy beams to install.

- Solution: Custom rigging plan, precise sling angle adjustments, strict exclusion zones, and real-time radio coordination.

- Outcome: Project completed ahead of schedule, incident-free, proving the value of local expertise and planning.

Future Trends in Steel Rigging for Sydney Projects

The rigging industry is evolving to meet increasing demands for safety and efficiency:

- AI-powered load monitoring: Real-time lift data prevents overloading.

- Drone-assisted site inspections: Enhances planning accuracy and hazard detection.

- Low-emission cranes: Supporting environmentally sustainable construction.

- Bigger, more complex lifts: Driven by mega-projects and high-rise development.

Final Thought: Expert Rigging is Non-Negotiable in Sydney Construction

Steel rigging is the backbone of Sydney’s construction industry. With tight urban spaces, heavy multi-tonne lifts, and strict safety codes, only experienced, certified rigging crews can ensure your project is delivered safely, on time, and to the highest standard.

📞 Call Hard Bakka Rigging today on 0415 878 744 or request a free quote to partner with Sydney’s trusted experts in structural steel rigging and crane services. to request a free quote from Sydney’s leading structural steel rigging specialists.