Steel Rigging Jargon Explained: 20 Terms Every Project Manager Should Know

Effective communication is the backbone of a safe, efficient construction site. When it comes to structural steel installation, misunderstanding rigging terminology can lead to misaligned lifts, project delays, and serious safety issues. Steel rigging terminology isn’t just tech speak—it’s the foundation of smart project management.

In this guide, we break down 20 essential steel rigging terms that project managers in Sydney and NSW should know. Understanding these terms enhances safety, streamlines project workflows, and improves collaboration between rigging teams, crane operators, and site supervisors.

Why Mastering Rigging Terminology Matters for Project Managers

Steel rigging involves lifting heavy, often awkwardly shaped components using cranes, slings, and a variety of rigging hardware. Miscommunication can result in accidents, down time, and cost overruns.

Here’s why mastering these terms is critical (especially for Sydney‑based projects in regulated environments like SafeWork NSW):

- Improved safety: Everyone understands the lift plan, hand signals, and exclusion zone requirements, reducing risk.

- Streamlined decision‑making: Clear terminology helps detect conflicts in lift plans or WLL (Working Load Limit) calculations early.

- Enhanced teamwork: Project managers who “speak rigger” speed up approvals and coordination with site crews.

- Regulatory compliance: Local guidelines (e.g., F.1, ISO 45001 certifications demanded by contractors like Hard Bakka Rigging) require clear rigging documentation and certified personnel.

Industry literature emphasises that miscommunication, particularly involving dogman/crane operator signals, is a root cause of many onsite accidents

Top 10 Basic Steel Rigging Terms Every Project Manager Should Know

Learn these commonly used terms to elevate communication and reduce guesswork — especially on everyday steel-lifting tasks:

- Shackle

A U‑shaped metal connector used to secure slings, chains, and lifting devices. Always ensure the shackle is rated for the intended load and compatible with slings or hooks. - Sling

A flexible lifting device—wire rope, chain, or synthetic—used to lift heavy loads. Different sling types have specific WLL (Working Load Limits) and inspection requirements. - Hoist

A device (manual, electric, or pneumatic) used to lift or lower loads vertically, often integrated into crane systems. - Working Load Limit (WLL)

The maximum safe load that rigging gear or crane attachments can support during normal lifting operations. Always plan around WLL—not breaking strength - Rigging Hardware

General term for gear such as hooks, eyebolts, turnbuckles, and chain links. Equipment must be rated, certified, and inspected regularly - Tagline

A guiding rope attached to a load to control its orientation during lifting—essential for avoiding swing and ensuring precise placement. - Dogman (Spotter)

A certified worker who communicates with the crane operator using standard hand or radio signals to ensure safe operations. - Boom Lift

A mobile elevated platform—used during rigging to access elevated positions for positioning steel or supervising the lift. - Spreader Beam

A below‑the‑hook device that distributes load weight evenly across multiple sling points to minimize stress and prevent damage - Crane Capacity Chart

A manufacturer‑provided chart showing safe lifting limits relative to boom length and load radius. Reviewing it helps avoid potential overload.

10 Advanced Rigging Terms for Complex Steel Installations

These terms are essential for managing larger scale projects—where lift precision and safety compliance are critical:

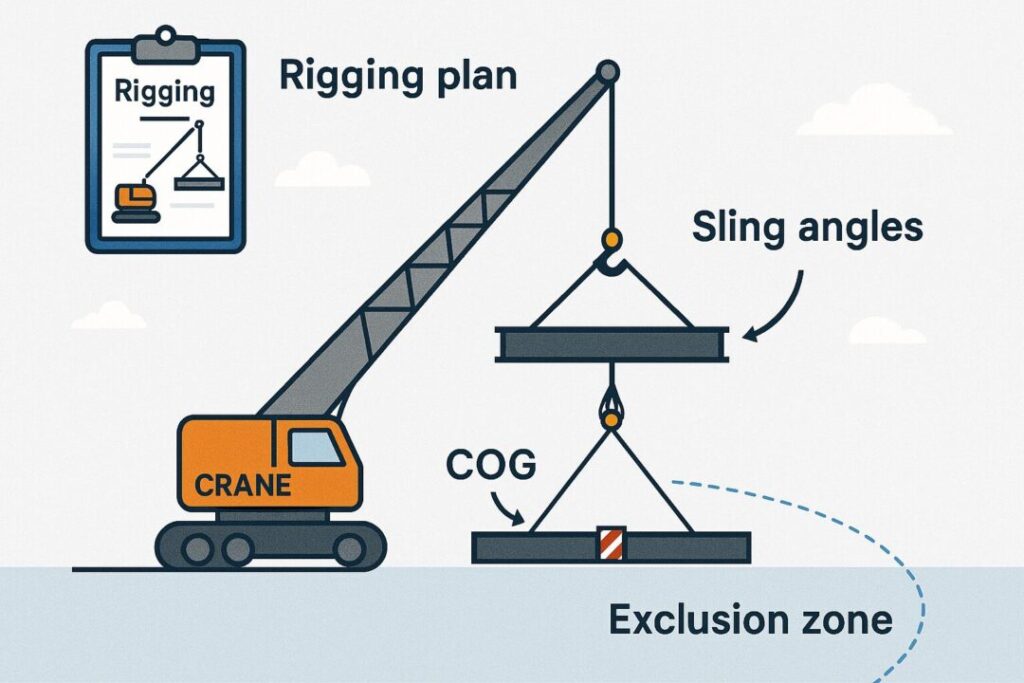

- Rigging Plan

A documented procedure that details equipment selection, sling configuration, lift sequence, weight calculations, sling angles, and safety zones. Used by certified riggers and overseen by dogmen. - Critical Lift

Any lift exceeding ~75% of crane capacity, involving proximity hazards, or unusual load configurations. These require extra planning, supervision, and safety checks. - Bridle Slinging

A method using multiple slings or legs attached to a load at different points to stabilize asymmetrical or awkward structures. - Load Chart De‑Rating

Adjusting a crane’s published capacity based on real-world conditions like boom angle, ground slope, or weather—critical to avoid overload. - Boom Deflection

The bending of a crane’s boom under load. When lifts require centimetre precision, understanding boom deflection becomes vital. - Softener (Padding)

Material placed between sharp load edges and slings to avoid damage to lifting gear and prevent load shift during lift. - Rigging Knots & Hitches

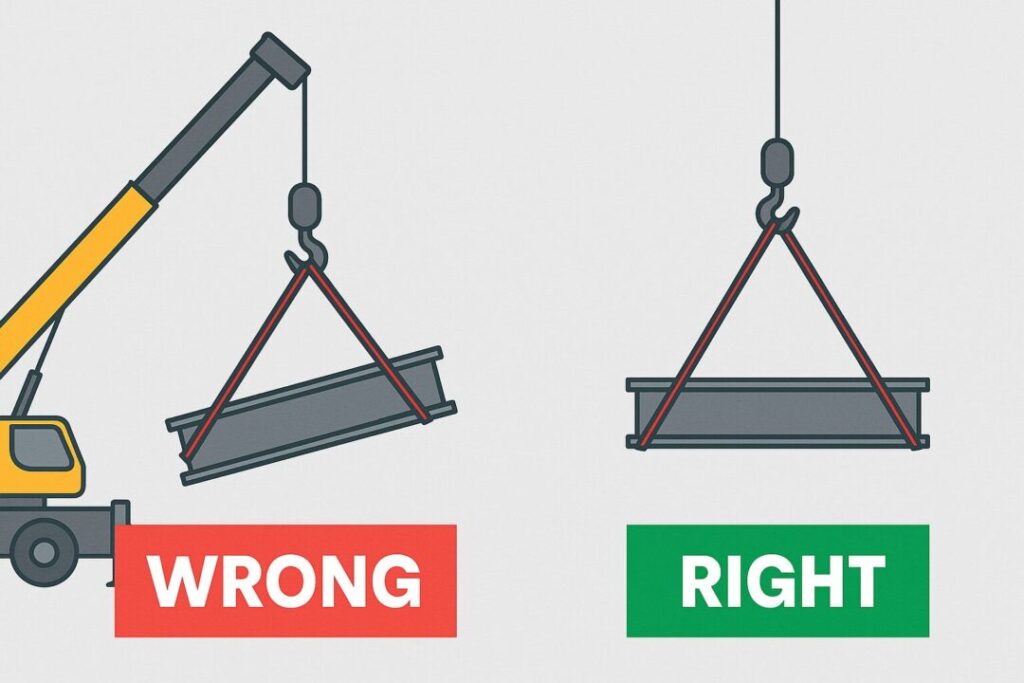

Specialised knot methods—such as basket hitch or endless sling configurations—to secure loads reliably. - So Called Centre of Gravity (COG)

The load’s balance point. Identifying and aligning what’s called COG with crane hook placement prevents tilting and unstable swings during lifts. - Exclusion Zone

A designated, roped‑off area around cranes and suspended loads to keep unauthorized personnel out during lift operations. - Load Test Certification

Official documentation confirming that lifting equipment, slings, shackles, and cranes have been load-tested and certified safe for use—required under standards like ASME B30.26 and SafeWork NSW inspection protocols

Common Terminology Mistakes That Project Managers Make

Even experienced project leaders sometimes trip up on rigging jargon—but the consequences can be significant:

- Confusing WLL with breaking strength: WLL is the permitted working limit, not the failure point.

- Ignoring sling angles: Sling angle reductions can significantly decrease WLL—proper planning prevents accidents.

- Misinterpreting crane signals: Inconsistent or unclear communication between dogman and operators can lead to unsafe lifting.

- Skipping a Rigging Plan: Lifts attempted without documented rigging plans and SWMS (Safe Work Method Statements) often lead to oversights and safety violations.

Pro Tip: Always request a Rigging Plan and SWMS from your rigging contractor. At Hard Bakka Rigging, we provide both for every project to guarantee compliance and clarity.

How Project Managers Can Master Rigging Terminology Quickly

You don’t have to become a rigging expert, but speaking the right language makes you a better project leader:

- Attend toolbox talks: Use them to ask riggers and crane operators questions and clarify procedures.

- Carry a rigging glossary on-site: Keeps definitions accessible under stress.

- Collaborate with certified crews—like those at Hard Bakka Rigging—where safety, communication, and expertise are front and centre.

- Use digital tools for lift planning: Apps and checklists help visualise rigging plans and apply accurate terminology in practice.

Emerging trends like VR training and lift simulation have shown measurable improvements in safety compliance and terminology retention across construction teams

Final Thought

Understanding steel rigging jargon is more than technical—it’s a critical leadership tool. By mastering these 20 key terms, project managers can ensure safer lifts, smoother communication, and more efficient timelines.

At Hard Bakka Rigging, we don’t just lift steel—we elevate standards. Our team meets ISO and SafeWork accreditation, provides full Rigging Plans and SWMS on every job, and delivers expert rigging support across Sydney and NSW.

📞 Ready to streamline your next rigging project? Call us at 0415 878 744 or visit our Contact page to request a free quote from Sydney’s leading structural steel rigging specialists.