Avoid costly errors and improve site safety with these expert rigging insights.

When it comes to structural steel installation, precision isn’t optional—it’s everything. One small rigging error can result in delays, damage, or serious safety hazards. Whether you’re a seasoned rigger, site supervisor, or project manager, understanding the most common rigging mistakes (and how to avoid them) is critical for safe and efficient operations.

In this guide, we’ll walk through the top 10 steel rigging mistakes that professionals encounter on construction sites—and offer practical strategies to prevent them.

1. Improper Load Calculations

Miscalculating the weight or centre of gravity of a load is one of the most dangerous rigging errors.

Why it happens: Relying on estimates or outdated drawings, or skipping load distribution analysis.

What to do instead: Always use accurate load data from engineering drawings or weigh the item if uncertain. Confirm load paths and centre of gravity before any lift. Consider using software or consult a lifting engineer for complex jobs.

2. Using Damaged or Unsuitable Rigging Gear

Chains, slings, and shackles wear down with use—and using compromised gear can be fatal.

Why it happens: Inadequate inspections or using the wrong gear for the job.

How to avoid it: Conduct daily visual checks and scheduled inspections per WHS and AS 4991 standards. Tag out and replace damaged gear immediately. Match your rigging gear to the load type, weight, and environmental conditions.

3. Ignoring Load Swing and Wind Conditions

Even small wind gusts can destabilise a suspended load.

Why it happens: Underestimating environmental factors or failing to secure taglines.

How to avoid it: Monitor wind speeds in real time. Use taglines for control, especially on large or awkward loads. Pause lifts during high winds, and always follow lift plans that factor in weather risks.

4. Poor Communication Between Crew Members

Misunderstandings between riggers, crane operators, and spotters can lead to dangerous missteps.

Why it happens: No clear signalling system or failure to assign roles.

How to avoid it: Use standard hand signals, radios, or agreed-upon calls. Assign a lead rigger to communicate directly with the crane operator. Conduct a team briefing before complex lifts.

5. Skipping the Pre-Lift Inspection and Toolbox Talk

Rushing into the first lift without a proper start can lead to mistakes later in the day.

Why it happens: Time pressure or lack of routine.

How to avoid it: Conduct a toolbox talk every morning. Review lift plans, PPE checks, site hazards, and equipment readiness. Make it a mandatory part of your start-up procedure.

6. Overloading Equipment Beyond Its Rated Capacity

Exceeding the working load limit (WLL) of a crane, sling, or shackle is a recipe for disaster.

Why it happens: Rushing, misreading capacity labels, or trying to “make it work.”

How to avoid it: Always verify the WLL and use proper load charts. Never exceed 80% of equipment capacity unless otherwise approved by an engineer. Use spreader bars or adjust sling angles to distribute weight correctly.

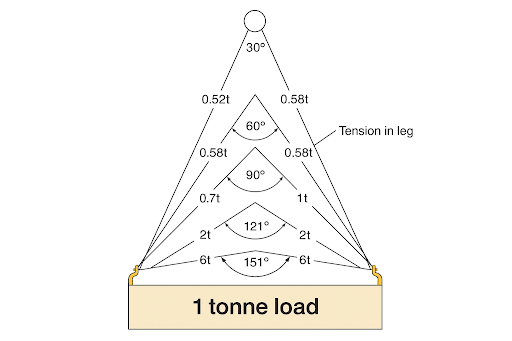

7. Improper Sling Angles and Hitch Configurations

The wrong sling angle can significantly increase stress on rigging components.

Why it happens: Lack of training or trying to lift with a “good enough” setup.

How to avoid it: Understand how sling angle affects tension. Keep angles as close to vertical as possible. Use the correct hitch type—vertical, choker, or basket—based on the load shape and balance.

8. Neglecting Regular Training and Licensing Requirements

Outdated skills or expired certifications can put teams at risk.

Why it happens: Overconfidence or lack of compliance checks.

How to avoid it: Ensure all riggers have valid High-Risk Work Licences (e.g. Dogging, Rigging) and receive refresher training. Stay updated on WHS regulations and encourage ongoing learning through workshops or online modules.

9. Failing to Document Lifts and Near Misses

Not recording what went wrong (or right) leads to repeated mistakes.

Why it happens: Poor site management or assuming “no harm, no foul.”

How to avoid it: Keep a lift log, document deviations, and report all near misses. Use these reports to update risk assessments and lift plans. It builds a culture of accountability and continuous improvement.

10. Neglecting Site-Specific Planning

Not every job site is the same—and treating them as such is risky.

Why it happens: Using generic plans or failing to assess ground conditions, obstacles, or layout.

How to avoid it: Conduct a site-specific risk assessment before each project. Adjust your lift plan for obstacles, traffic zones, underground services, and uneven ground. Tailor your rigging strategy to the project, not the other way around.

Frequently Asked Questions

Q: What qualifications should a steel rigger have in Australia?

A: Steel riggers should hold a valid High-Risk Work Licence (Dogging and/or Rigging) issued by SafeWork NSW or the relevant authority in their state. Additional certifications, such as Working at Heights, Confined Spaces, and EWP operation, are often required for certain job sites.

Q: How often should rigging equipment be inspected?

A: Rigging gear should be visually inspected before every use, with formal inspections carried out at intervals specified by AS 4991 and manufacturer guidelines—typically every 3–6 months depending on usage.

Q: What is the safest sling angle for lifting steel?

A: The closer the sling angle is to 90° (vertical), the safer and more stable the lift. Angles less than 60° can dramatically increase tension on the sling, increasing the risk of failure.

Q: How can I ensure my site-specific lift plan is effective?

A: A good lift plan includes accurate load data, crane selection, rigging gear specifications, environmental considerations, crew responsibilities, and contingency plans for unexpected conditions.

Q: Does Hard Bakka Rigging offer crane hire as part of their rigging service?

A: Yes, we offer both wet and dry crane hire, including our 30-tonne XCMG mobile crane, with fully certified operators to handle projects across Sydney and NSW.

Final Thoughts: Lift Smart, Rig Safe

Steel rigging isn’t just about brute strength—it’s about foresight, communication, and control. By avoiding these 10 common mistakes, your team can reduce downtime, improve safety, and stay on budget.

At Hard Bakka Rigging, we bring decades of expertise to every structural steel project—from heavy lifts to complex assemblies. Our certified riggers, safety-first protocols, and tailored lift plans ensure every beam is placed with confidence.

🔧 Need help with steel rigging for your next job?

📞 Contact us today at +61 415 878 744 or visit www.hardbakkarigging.com.au to get a free quote.🌐 www.hardbakkarigging.com.au!