Steel Rigging Innovations 2025: BIM, Drones, Advanced Gear & Sustainable Lifting Solutions

Steel rigging is the backbone of modern construction, enabling safe and efficient assembly of everything from commercial buildings to large-scale infrastructure. As projects become more complex, the industry is evolving to adopt innovative technologies and methods that enhance safety, precision, and project timelines.

In this article, we explore the key innovations shaping steel rigging in 2025 and beyond, focusing on advancements that deliver real value to clients while improving operational excellence.

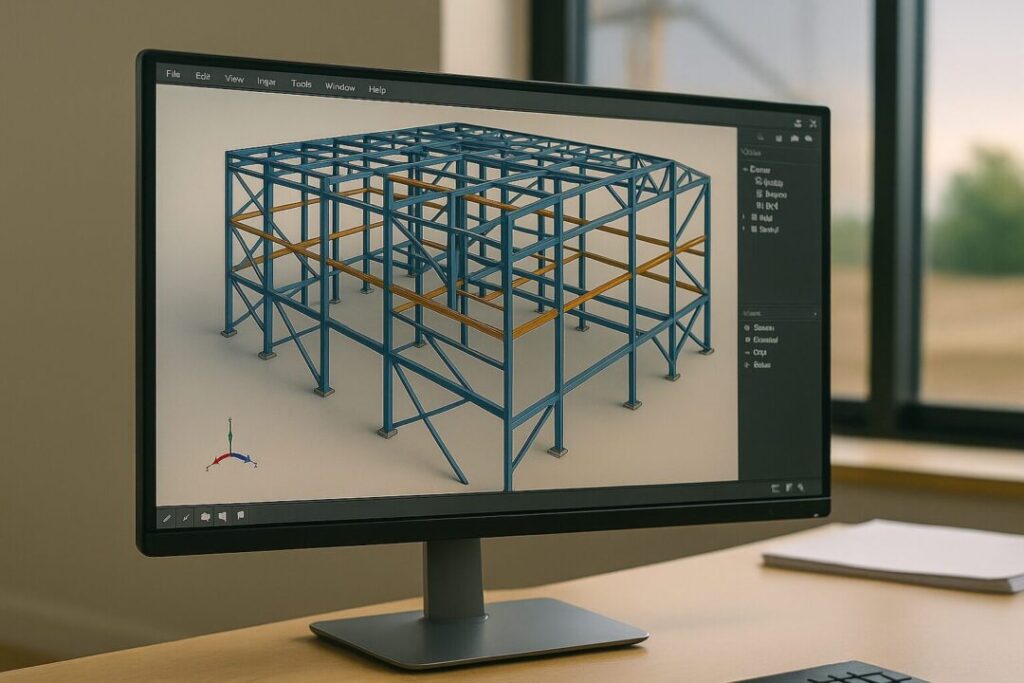

1. Digital Planning with BIM and 3D Modelling

Building Information Modelling (BIM) and 3D simulation tools are transforming how rigging projects are planned and executed.

- Digital models allow teams to visualise lifts before arriving onsite, reducing unforeseen challenges.

- Clash detection ensures beams, cranes, and other elements don’t interfere during lifts.

- Project managers benefit from accurate scheduling and sequencing, helping to keep projects on track.

This proactive planning minimises risk, saves time, and ensures a smoother installation process.

2. Drone-Assisted Site Surveys

Drones provide fast and precise aerial data, giving rigging teams a clearer view of site conditions.

- They reduce manual inspection time, allowing teams to assess site access and lifting zones safely.

- Drones help verify that delivery routes, crane positions, and load paths are clear before steel arrives.

- Combined with BIM, they enhance lift planning accuracy and reduce onsite adjustments.

This technology supports safer, more efficient rigging operations, particularly on complex or restricted-access sites.

3. Advanced Rigging Hardware

Traditional rigging gear is evolving with smart technology for enhanced safety and control:

- Load-sensing shackles and hooks send real-time weight data to supervisors.

- Synthetic high-strength slings are easier to handle and reduce manual strain while maintaining lifting capacity.

- Automated release systems allow for safe detachment of loads in high or hard-to-reach positions.

These upgrades give rigging teams better information and control, resulting in precise, well-executed lifts.

4. Safety-Driven Wearable Technology

New safety solutions are making job sites even safer:

- Wearable sensors track proximity to hazardous zones and can alert workers instantly.

- Refresher VR training simulations help crews prepare for challenging lifts before stepping onsite.

- Crane anti-collision systems prevent accidental contact with structures or other machinery.

At Hard Bakka Rigging, safety remains a non-negotiable priority, and these technologies help uphold the highest standards on every project.

5. Sustainable Practices in Rigging

Sustainability is becoming a greater focus across construction, and rigging is no exception:

- Hybrid and electric-powered cranes reduce emissions on job sites.

- Green steel options produced with lower carbon outputs are increasingly available.

- Modular and recyclable components support waste reduction and reusability.

Innovative rigging solutions now help clients meet environmental goals without compromising project outcomes.

6. Data-Driven Project Management

Real-time data collection and analytics are making rigging more predictable and measurable:

- Live load monitoring during lifts ensures safe working limits are never exceeded.

- Digital reporting tools keep stakeholders informed and ensure compliance with Australian safety standards.

- Predictive maintenance technology minimises downtime, ensuring equipment reliability throughout a project.

This data-focused approach strengthens planning accuracy and supports informed decision-making.

Conclusion

The future of steel rigging is defined by safer, smarter, and more sustainable solutions. Innovations in digital planning, drone technology, smart rigging gear, and data-driven safety systems are helping contractors deliver projects more efficiently while maintaining the highest safety and quality standards.

At Hard Bakka Rigging, we remain committed to adopting proven innovations that benefit our clients and improve project outcomes. With over 30 years of combined experience, we bring expertise, precision, and forward-thinking methods to every steel rigging project across NSW.

📞 Contact Bill Bakka: +61 415 878 744

📩 Email: sales@hardbakkarigging.com.au

🌐 Website: www.hardbakkarigging.com.au costly mistakes but also elevate the quality of every steel project you handle.